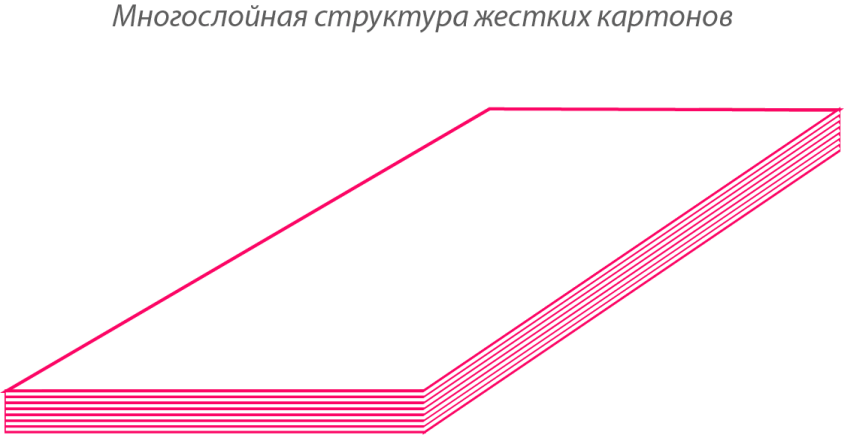

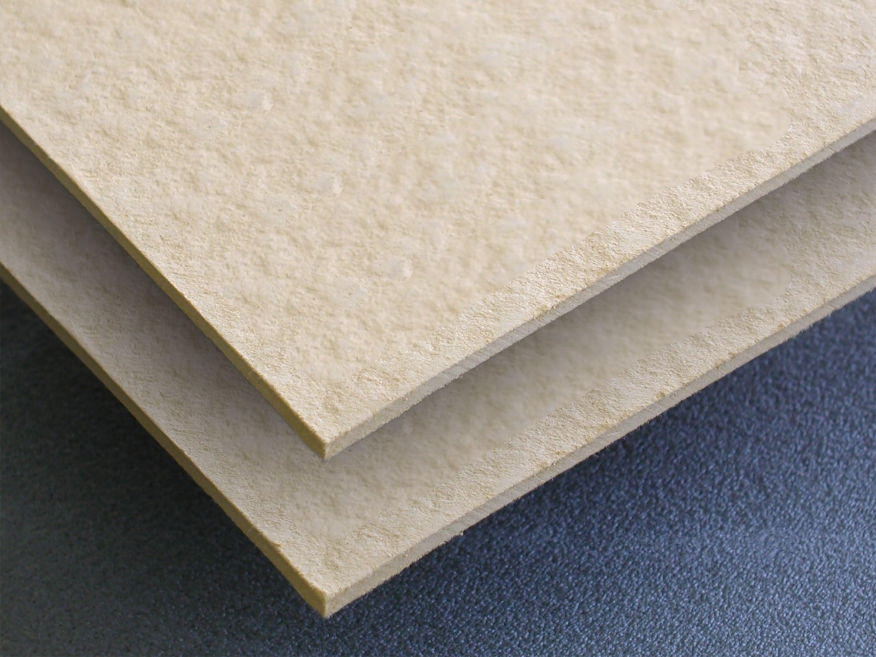

Rigid Millboards

Rigid millboards are used as gaskets, heat shields, furnace lining and heat insulation layers in equipment or construction.

They come as sheets with thickness from 2 to 10 mm.

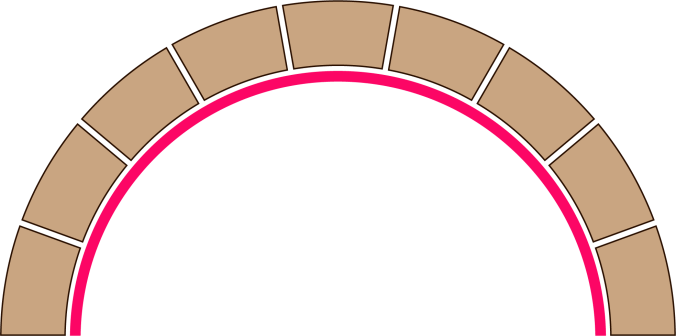

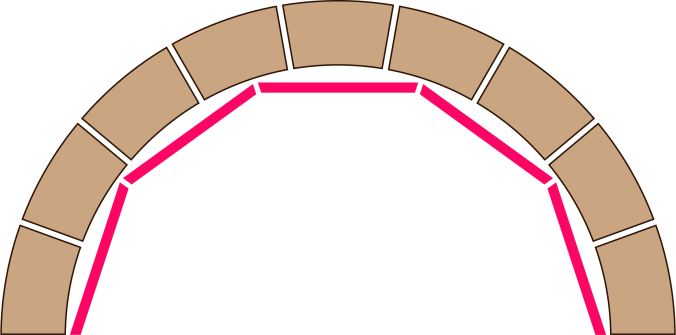

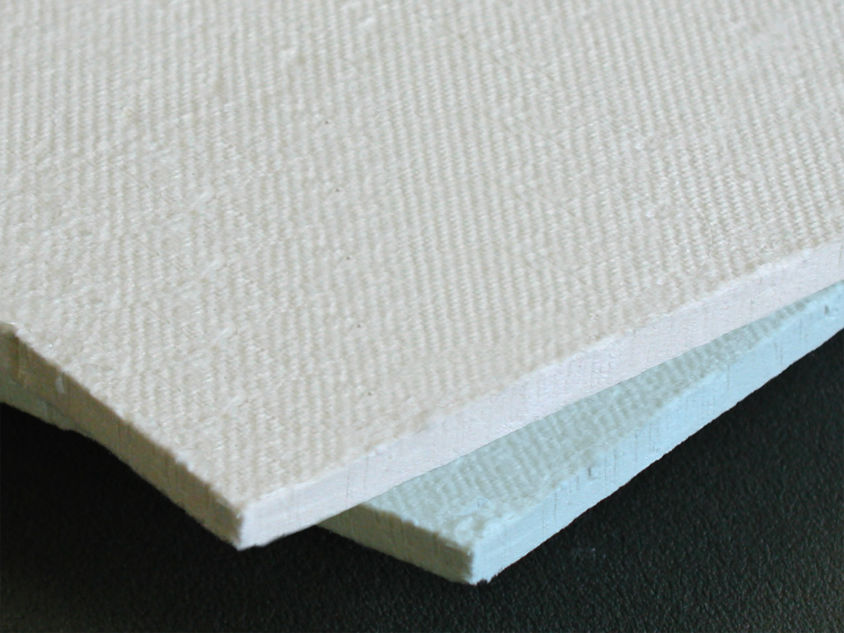

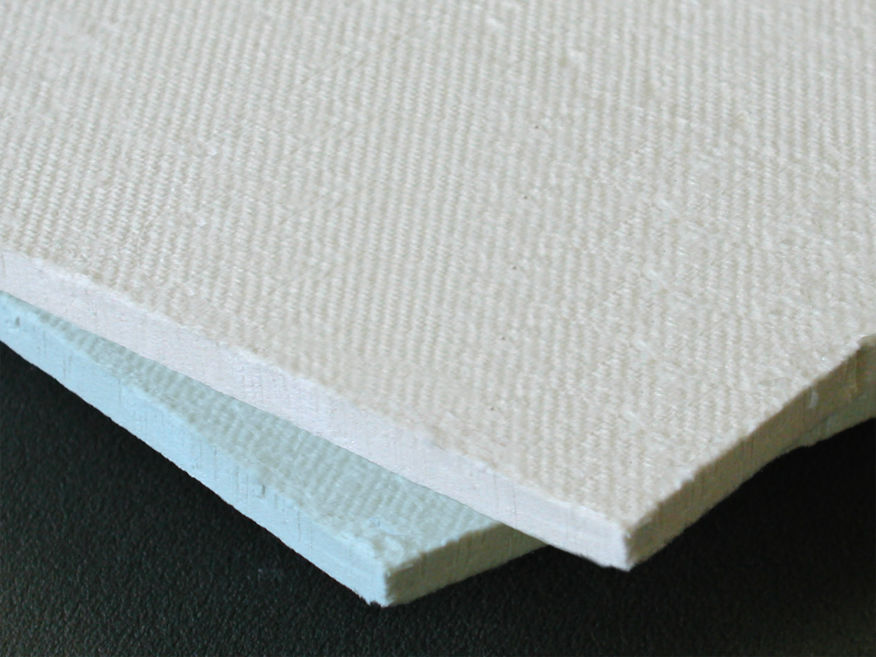

Molded Boards

The cartons manufactured by the molding method have low thermal conductivity and are used as gaskets, insulating layers, etc. These cartons can stay in an open fire for a long period of time.

Molded cartons are supplied as sheets with thickness from 5 to 25 mm.

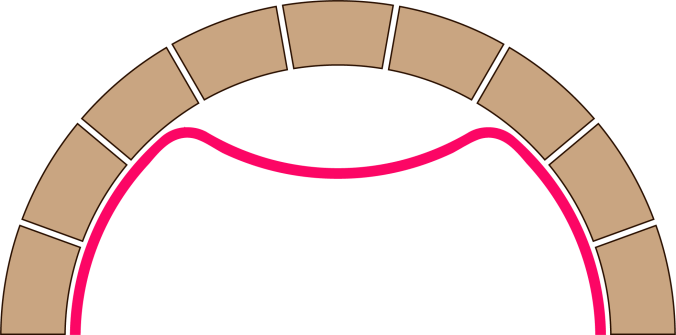

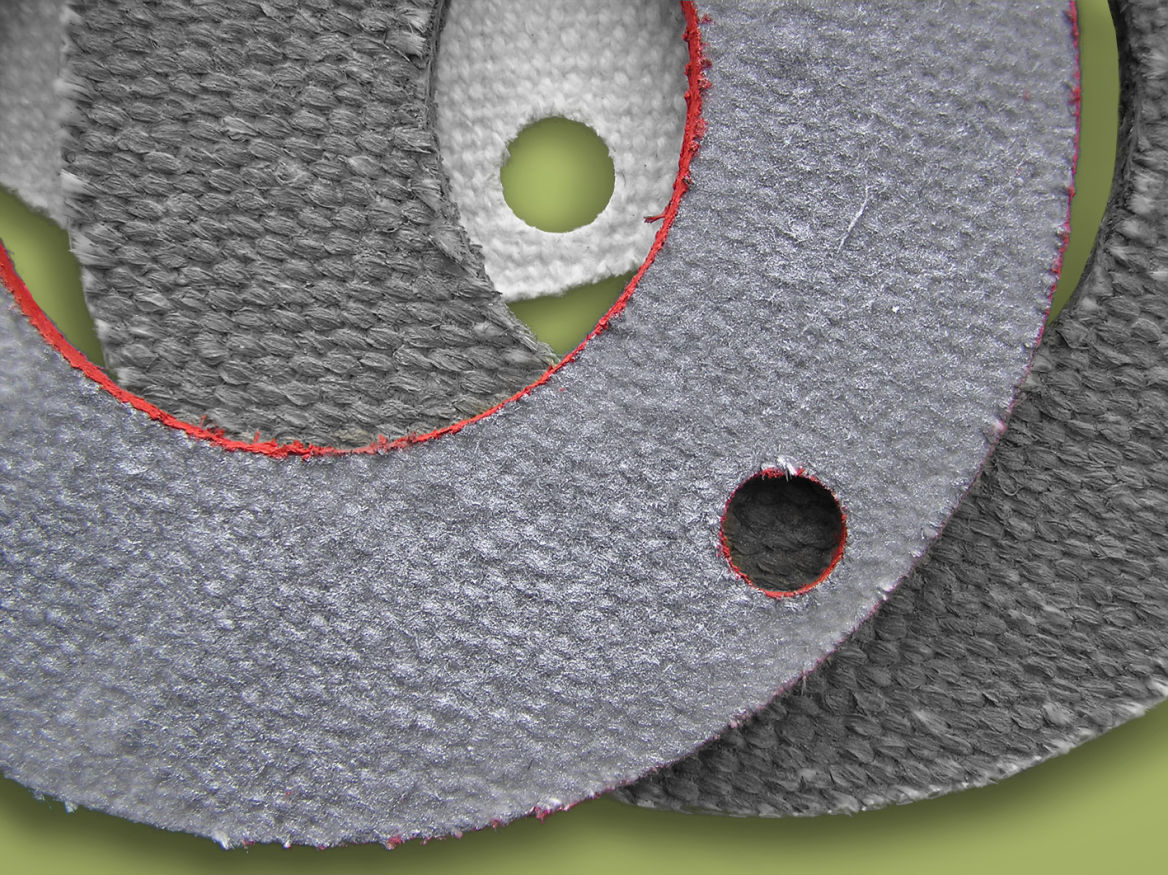

Flexible Cartons

Flexible cartons are used for insulating curved surfaces. They are also used for furnaces lining, mould insulation, as fireproof doors’ fillers and as inner layers of high temperature gases compensators.

They are supplied as rolls with thickness from 0.5 to 6 mm.