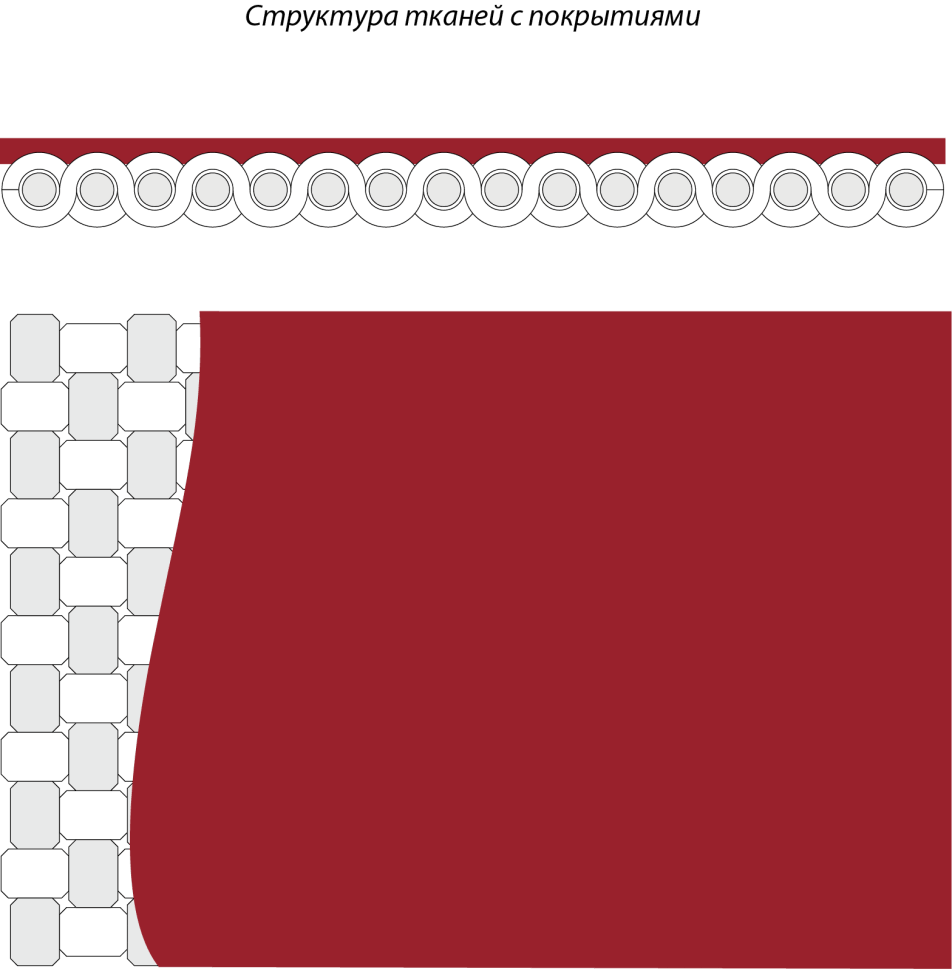

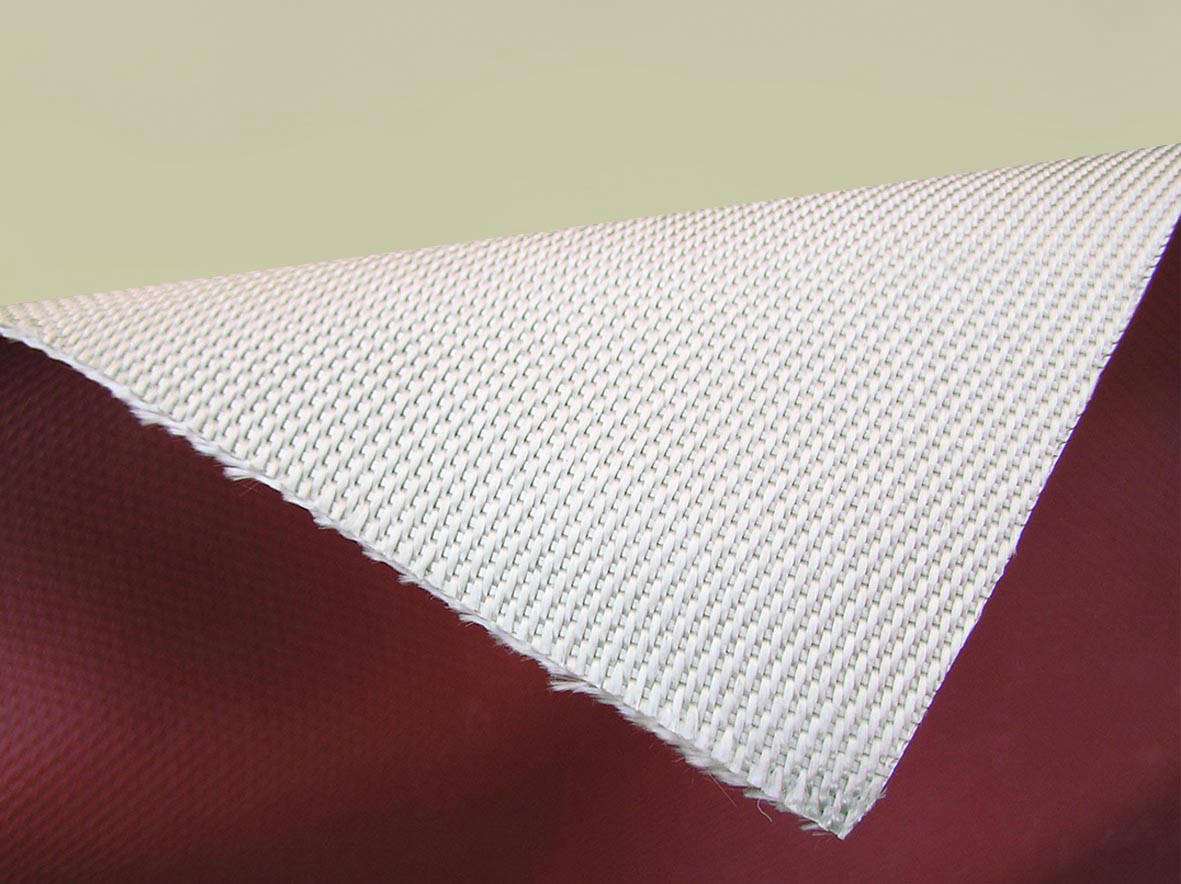

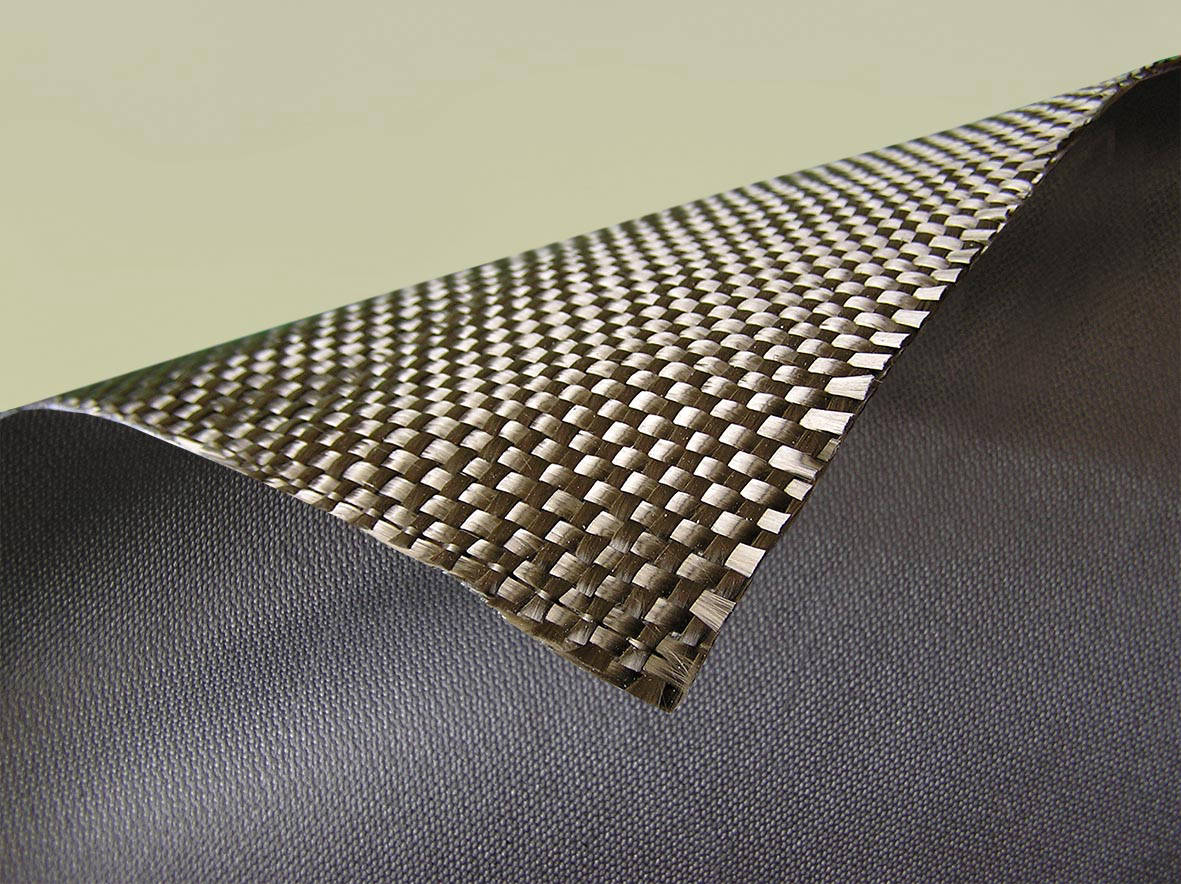

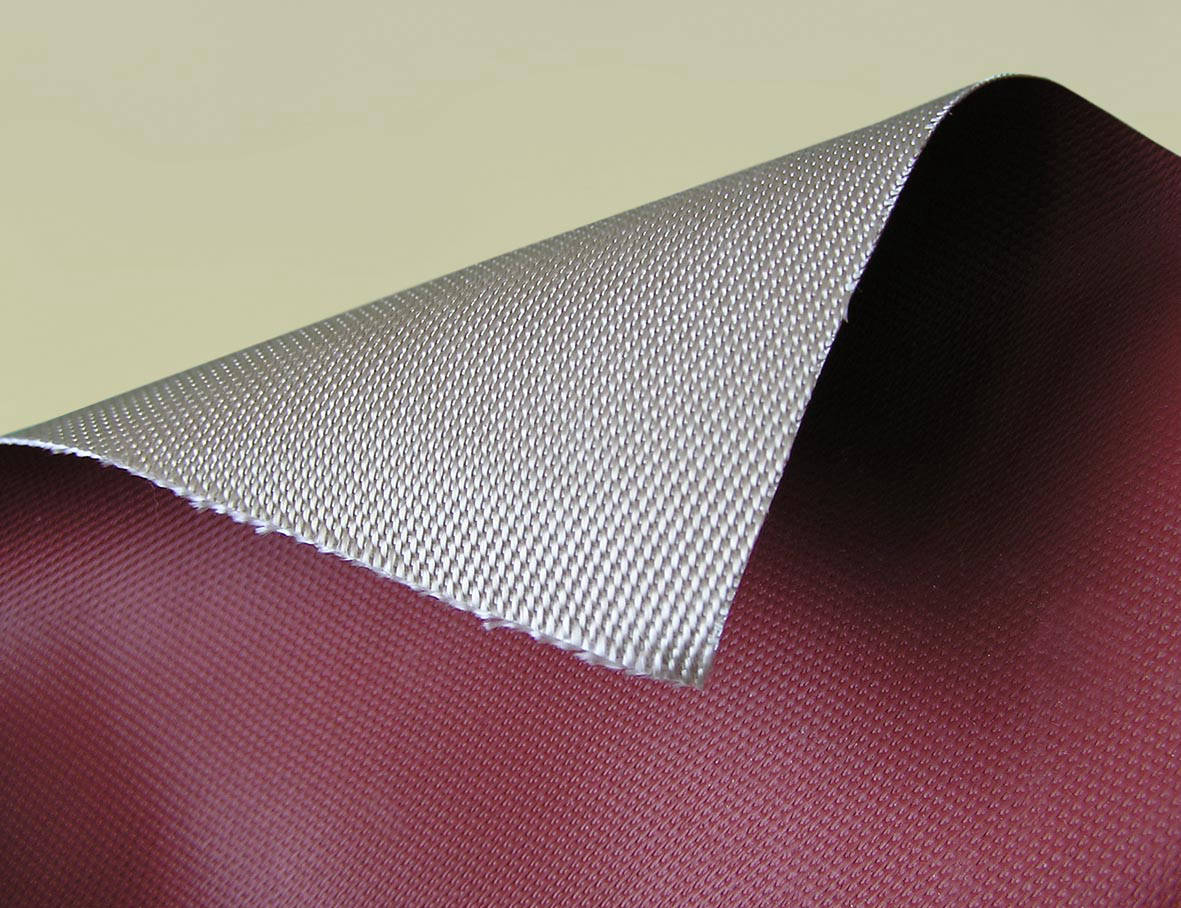

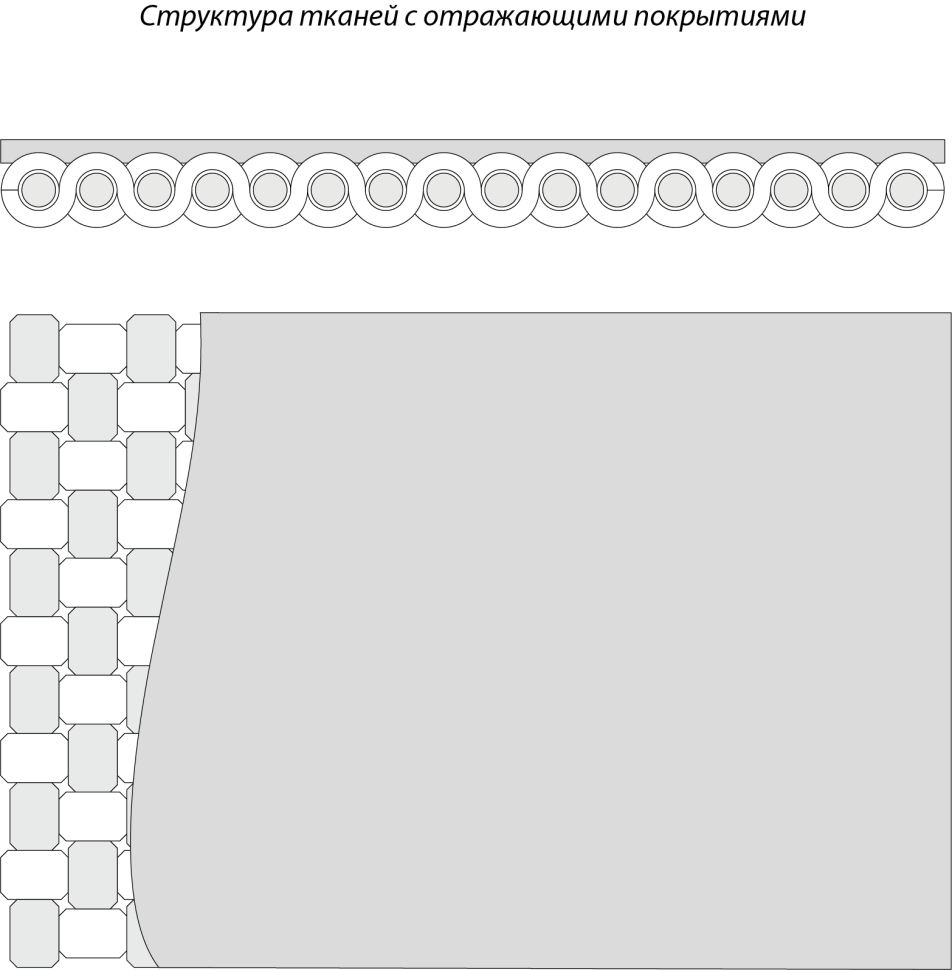

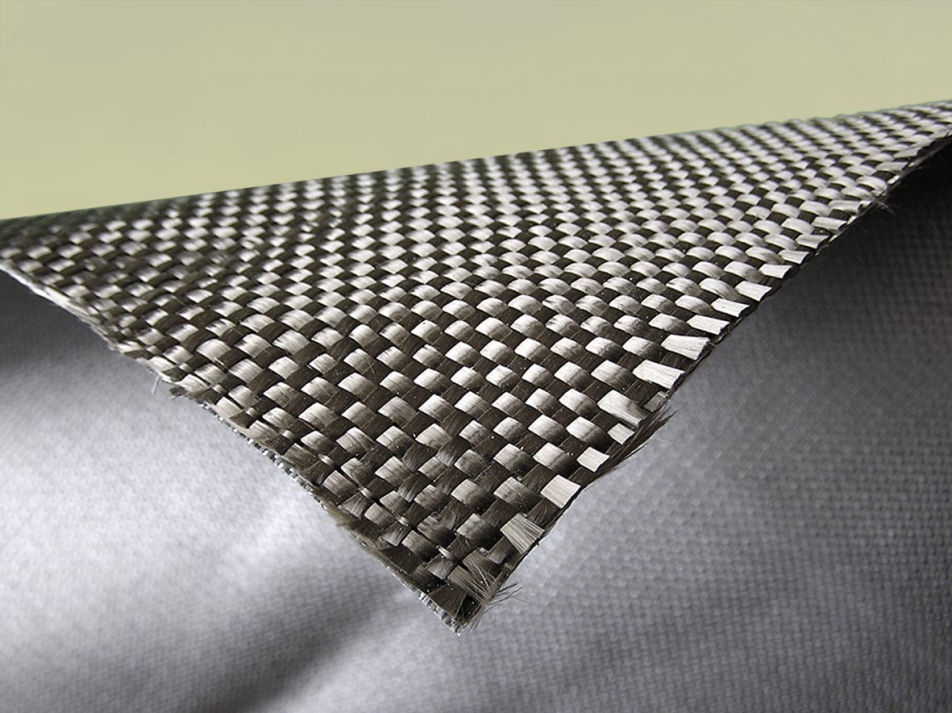

The Material Choice

The materials choice is an important process in our production. Sometimes we use unconventional fibers to reach the goal and the final result usually exceed customer expectations.

Yarns Preparation

A combination of different fibers is often needed for producing high quality textile materials. We have all the equipment needed for preparing complex threads.

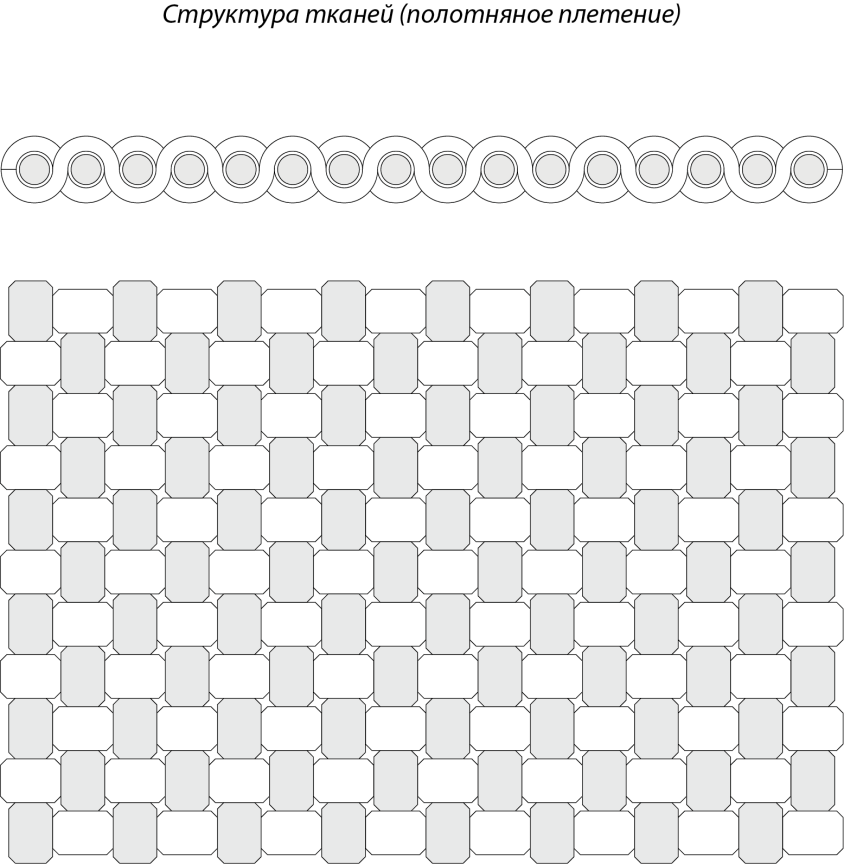

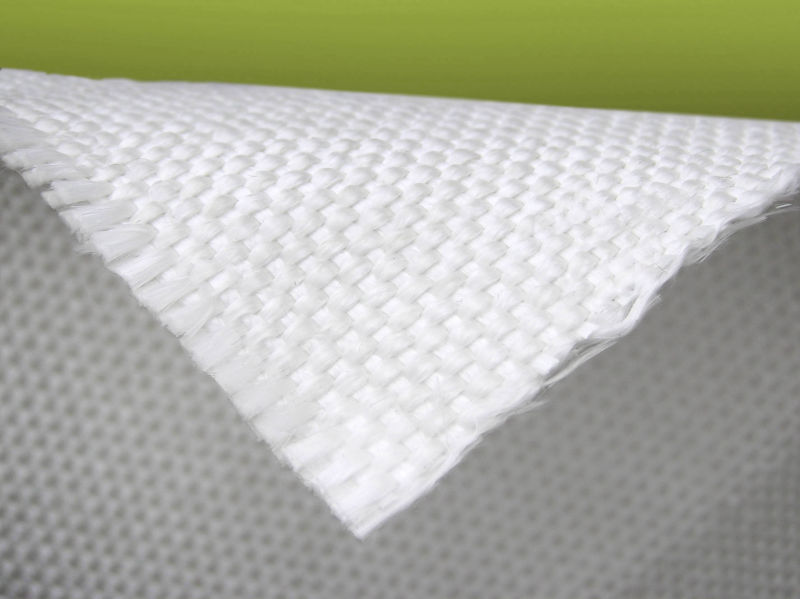

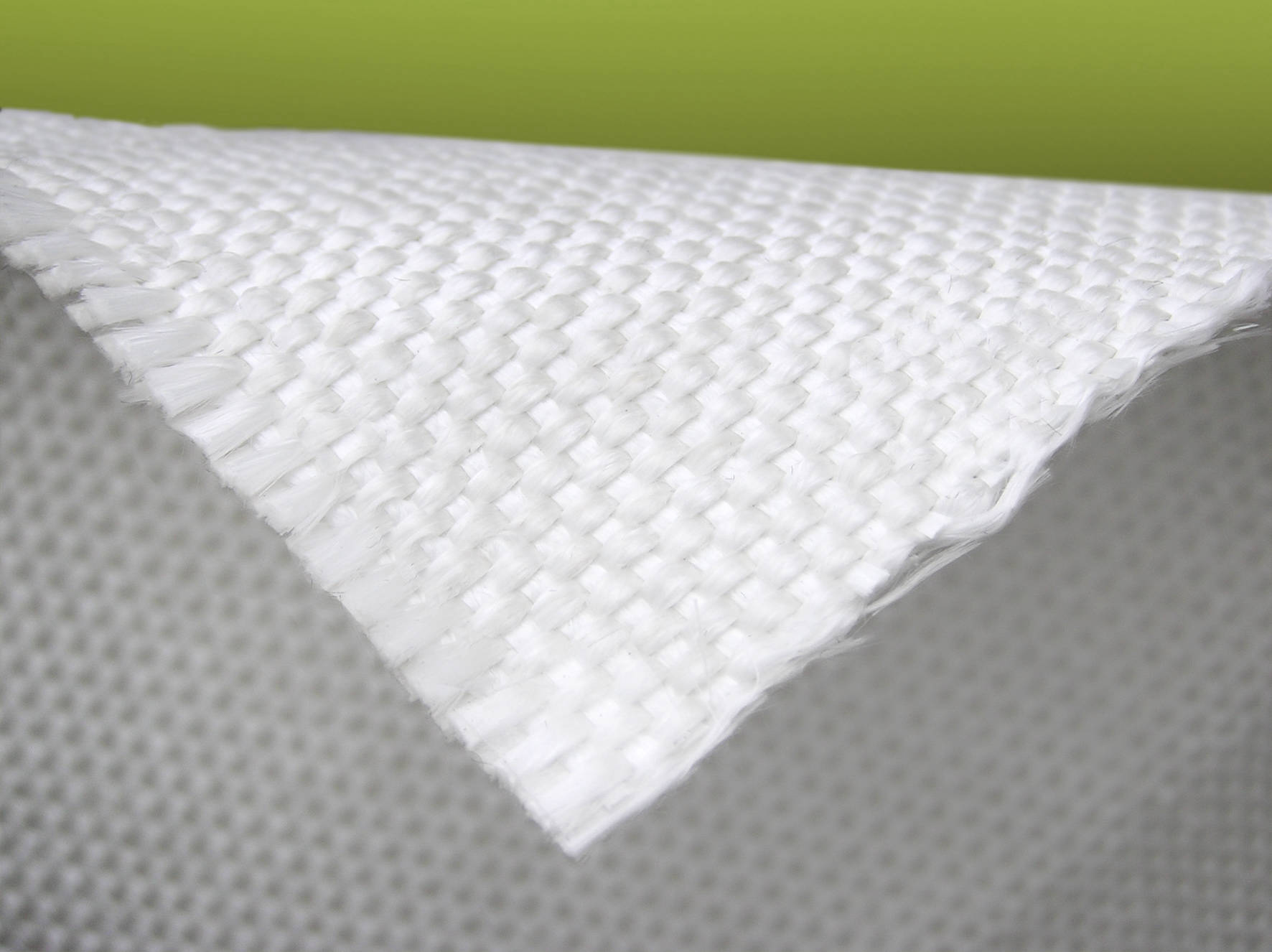

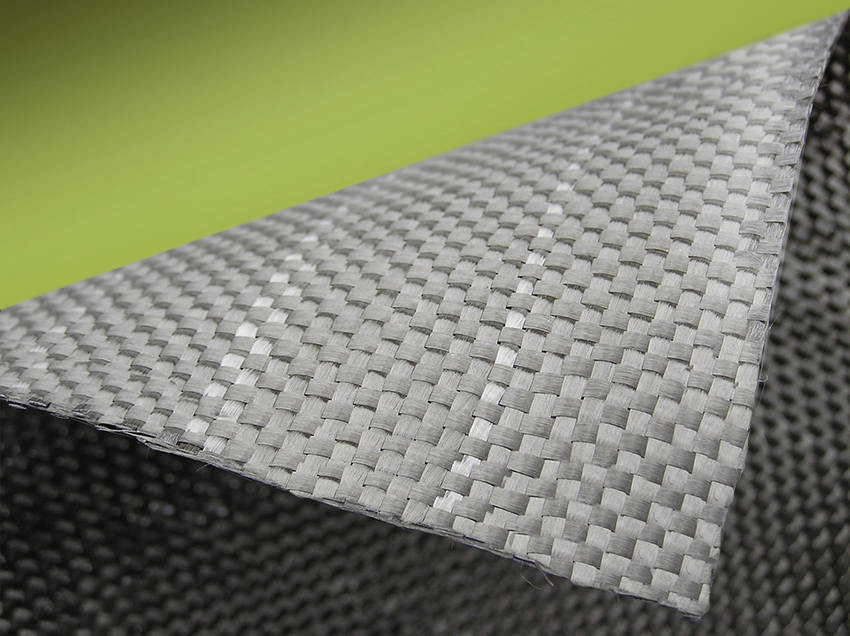

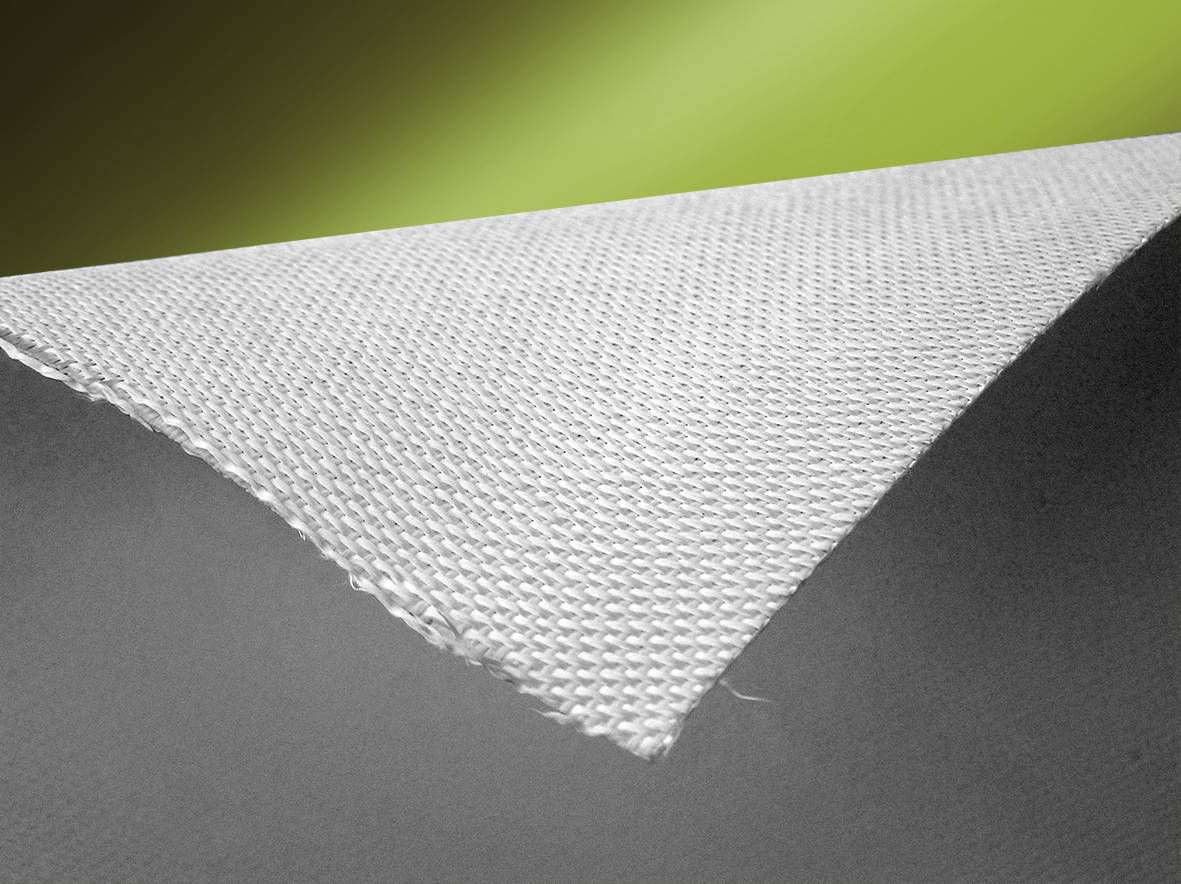

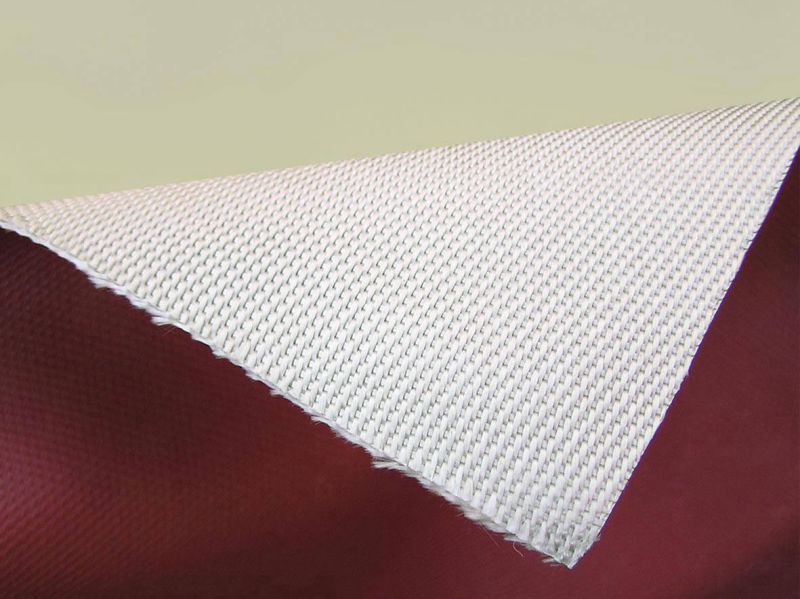

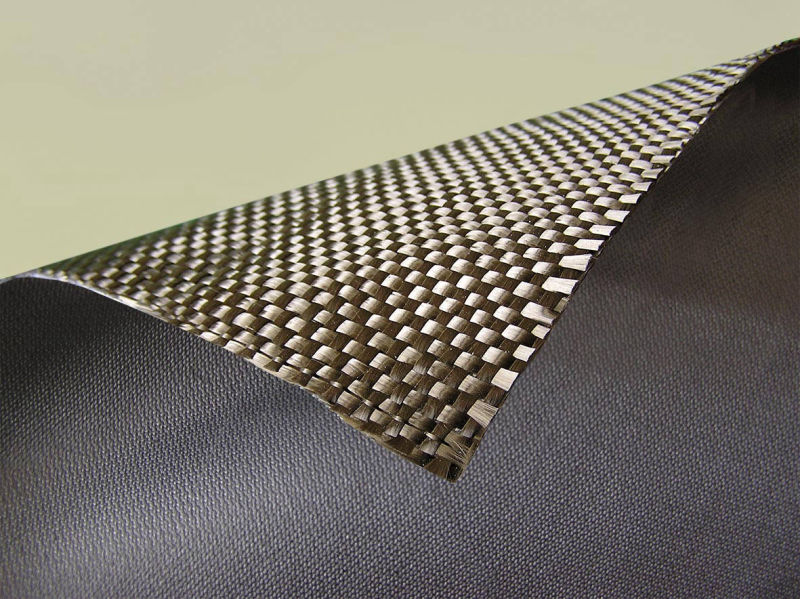

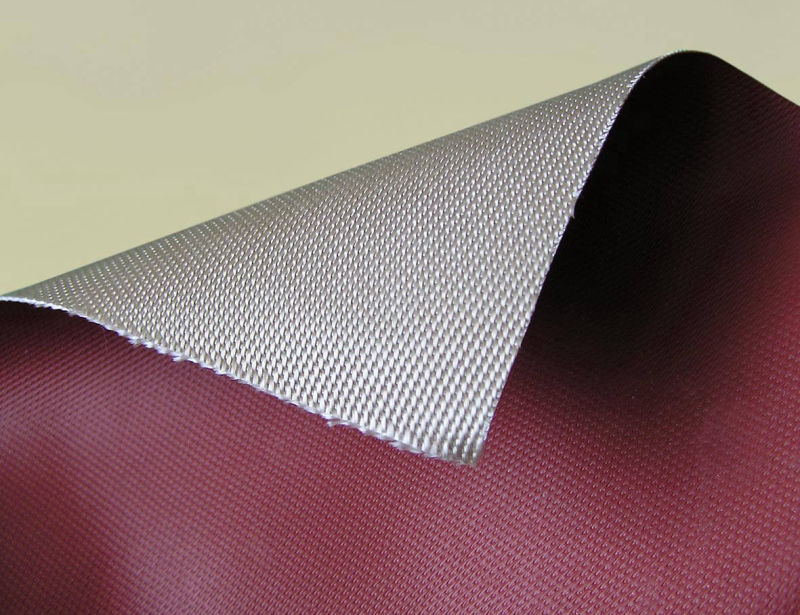

Weaving process

The weaving process is carried out on two types of machines, depending on the type of tissues and needed thickness.

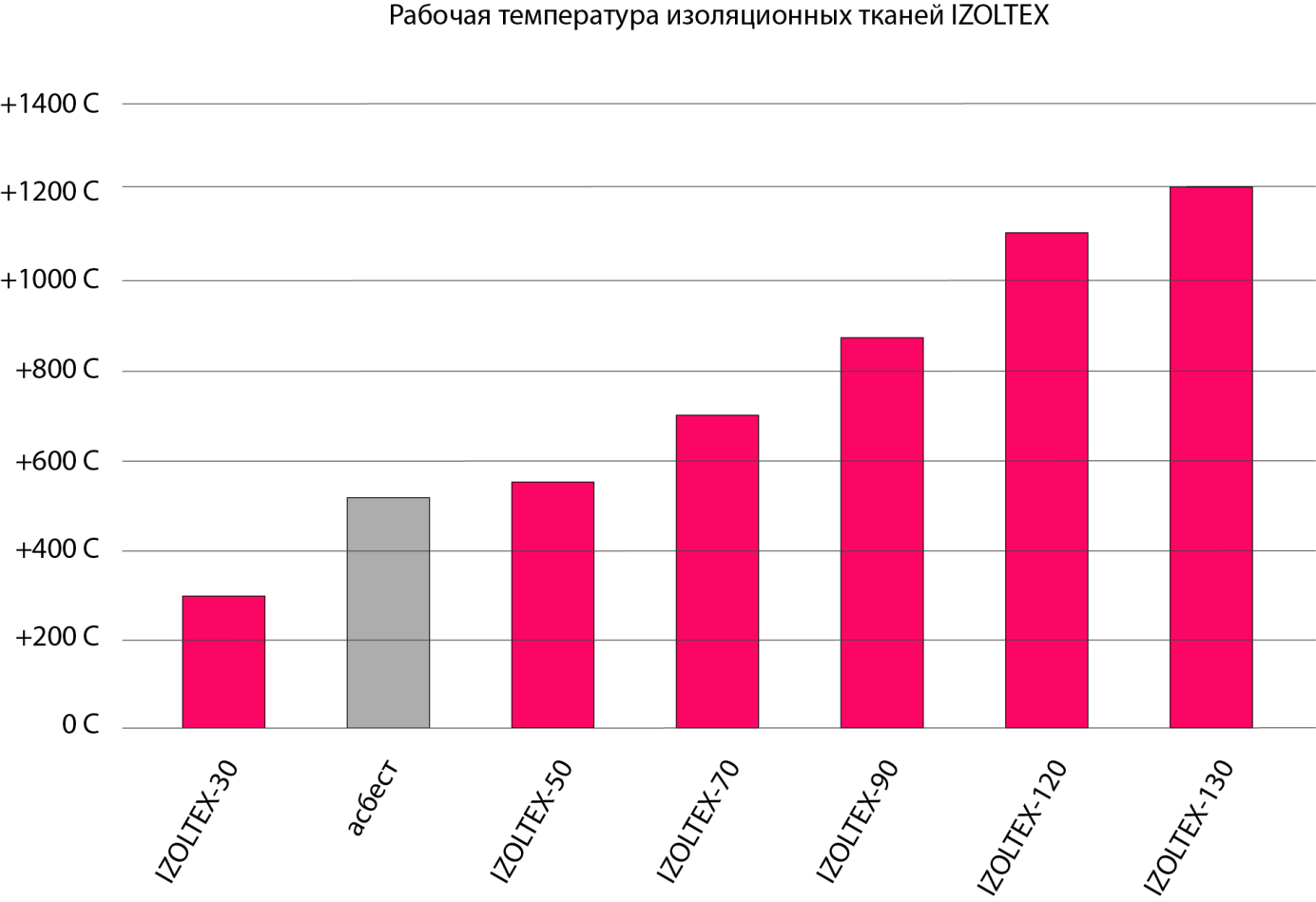

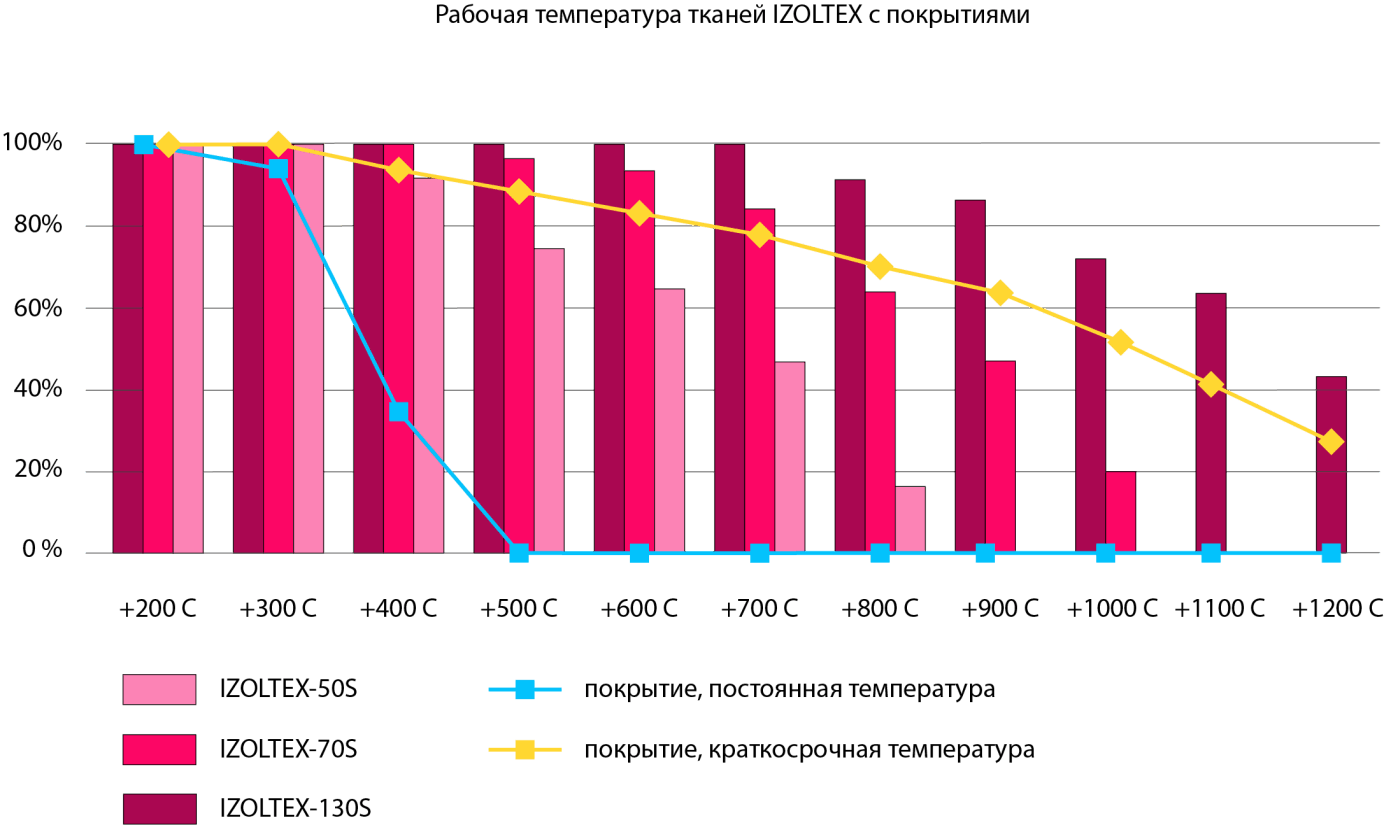

Testing

All our products are periodically tested in laboratory furnaces in different temperature modes. Having our own laboratory equipment greatly facilitates the innovative research of our employees.