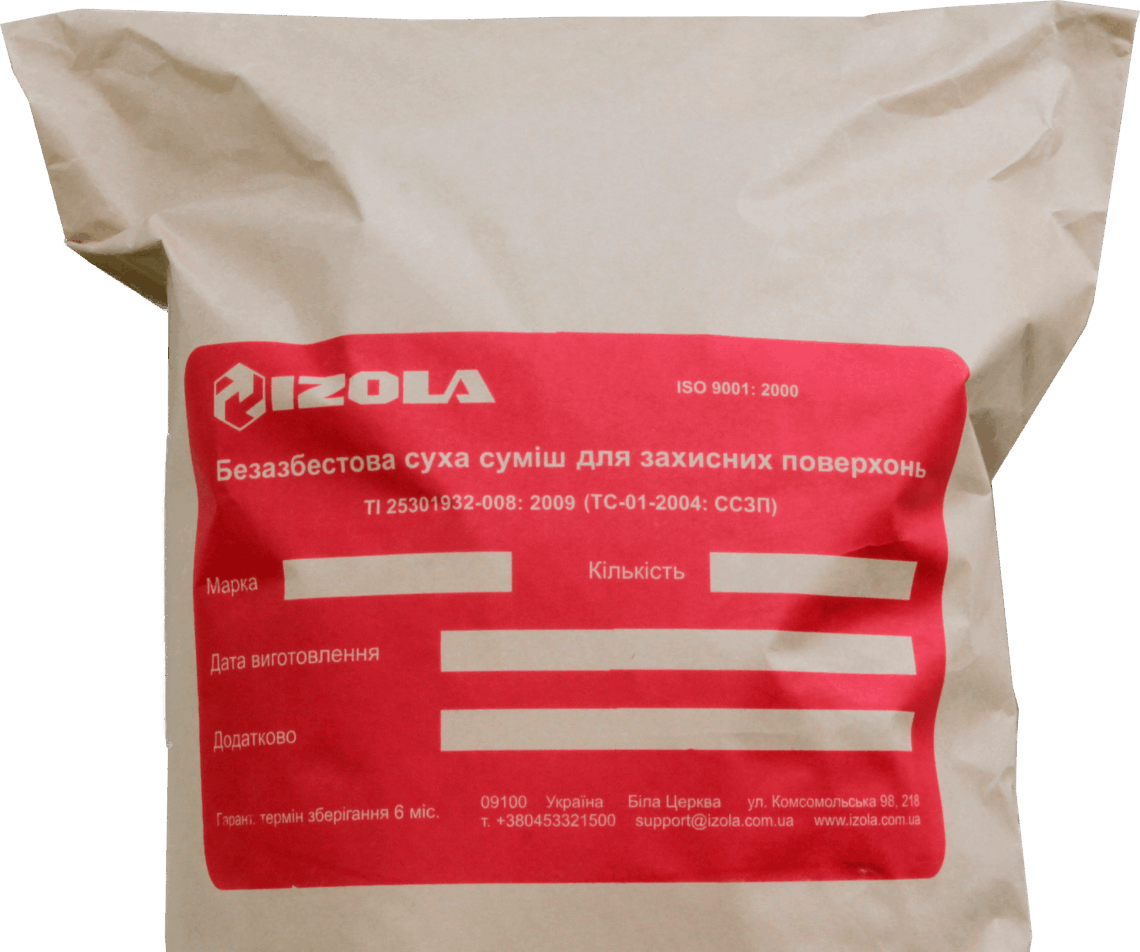

Dry mixtures for protecting surfaces

The main purpose of the mixtures is to be used as solutions for manufacturing constructional heat insulating protective structures, such as heat pipes, heat exchangers, chambers, boilers, etc, which are located in the open air or indoors.